As I mentioned in my prior post, there are a lot of people promoting the application of Lean Manufacturing principles in sales. There is a lot we can learn, at the same time, there are huge areas where the comparisons break down.

If you haven’t read the first post, What We Can Learn From Lean Manufacturing, be sure to read this. This post continues on the foundation of Toyota Production System’s 4 P’s, by diving into the 14 principles. Recapping them briefly:

Philosophy as the foundation:

Principle 1: Base your management decisions on a long term philosophy, even at the expense of short-term financial goals.

The right process will produce the right results:

Principle 2: Create a continuous process flow to bring problems to the surface.

Principle 3: Use “pull” systems to avoid overproduction.

Principle 4: Level out the workload.

Principle 5: Build a culture of stopping to fix problems, to get quality right the first time.

Principle 6: Standardized tasks and processes are the foundation for continuous improvement and employee empowerment.

Principle 7: Use visual control so no problems are hidden.

Principle 8: Use only reliable, thoroughly tested technology that serves your people and processes.

Add value to the organization by developing your people.

Principle 9: Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

Principle 10: Develop exceptional people and teams who follow your company’s philosophy.

Principle 11: Respect your extended network of partners and suppliers by challenging them and helping them improve.

Continuously solving root problems drives organizational learning.

Principle 12: Go and see for yourself to thoroughly understand the situation.

Principle 13: Make decisions slowly by consensus, thoroughly considering all options. Implement decisions rapidly.

Principle 14: Become a learning organization through relentless reflection and continuous improvement.

Principle 1: Base your management decisions on a long term philosophy, even at the expense of short term financial goals. This, as you’ve come to learn is not unique to manufacturing, it’s sound business practice. In sales and marketing, we tend, however to be driven by the opposite, we are focused on today, this week, this month, this quarter.

We constantly shift priorities, we create programs du jour, abandoning them for the next cool idea. Inevitably, this short term focus and shifts in priorities has an adverse impact on our people and customers, and ultimately the results we achieve. Both our people and customer get confused with these constant shifts. Our people never get the opportunity to master the program execution, when things are shifted and they have to start again.

For sustained performance improvement, to hit our goals year after year, to retain and grow our relationships with customers, we have to have a long term view of our own business goals and strategies, and a goal of creating customers for life. Built on this platform, we build the strategies, programs, develop/train our people, and execute our strategies. We learn and build on that platform, sharpening the capabilities of our organization and each individual.

Principle 2: Create a continuous process flow to bring problems to the surface. As you have already seen, the foundation is “the right process will product the right results.” If we don’t have processes in place, that our people are using, then we have no way to truly understand what works and what doesn’t work. Having processes in place helps us identify problems, roadblocks, failures; enabling us to correct them and improve the results produced.

The sales process is fundamental. How do we increase our win rates, decrease our sales cycle time, increase average deal value/margin unless we have a process that people are using. In executing the process, we start to see where the problems are. Are we targeting the right customers, are we aligned with their buying process, are we working with the right people….. There are any number of problems we encounter in finding and qualifying deals, but those problems are difficult to identify unless we have a process.

There are many processes and workflows critical to our success in driving performance in our sales and marketing organizations. Without these we have no idea of what our problems are, which are the highest priority, and how we begin to improve them.

Imagine an organization where we have no processes in place. It would be utter chaos. If that organization wasn’t achieving it’s goals, where would we start in looking to improve performance? Is it our customer engagement strategies, is it problems with our sweet spot, do we have the right people, do we have the right skills, do we know how to reach and engage the customers……… It could be anything and everything.

Processes provide the basis for understanding what drives performance and for identifying where we can improve performance.

Principle 3: Use “pull” systems to avoid overproduction. This is one of the most misunderstood principles in applying manufacturing methods to sales and marketing. In the old days of manufacturing, production was separated from customer demand. The principle was “build to stock.” In these systems, manufacturing executives provided their best guess about what they should build, they built it, and put it in inventory. This caused huge inefficiencies. They would build the wrong products–wasting resource and money on product that couldn’t be sold.

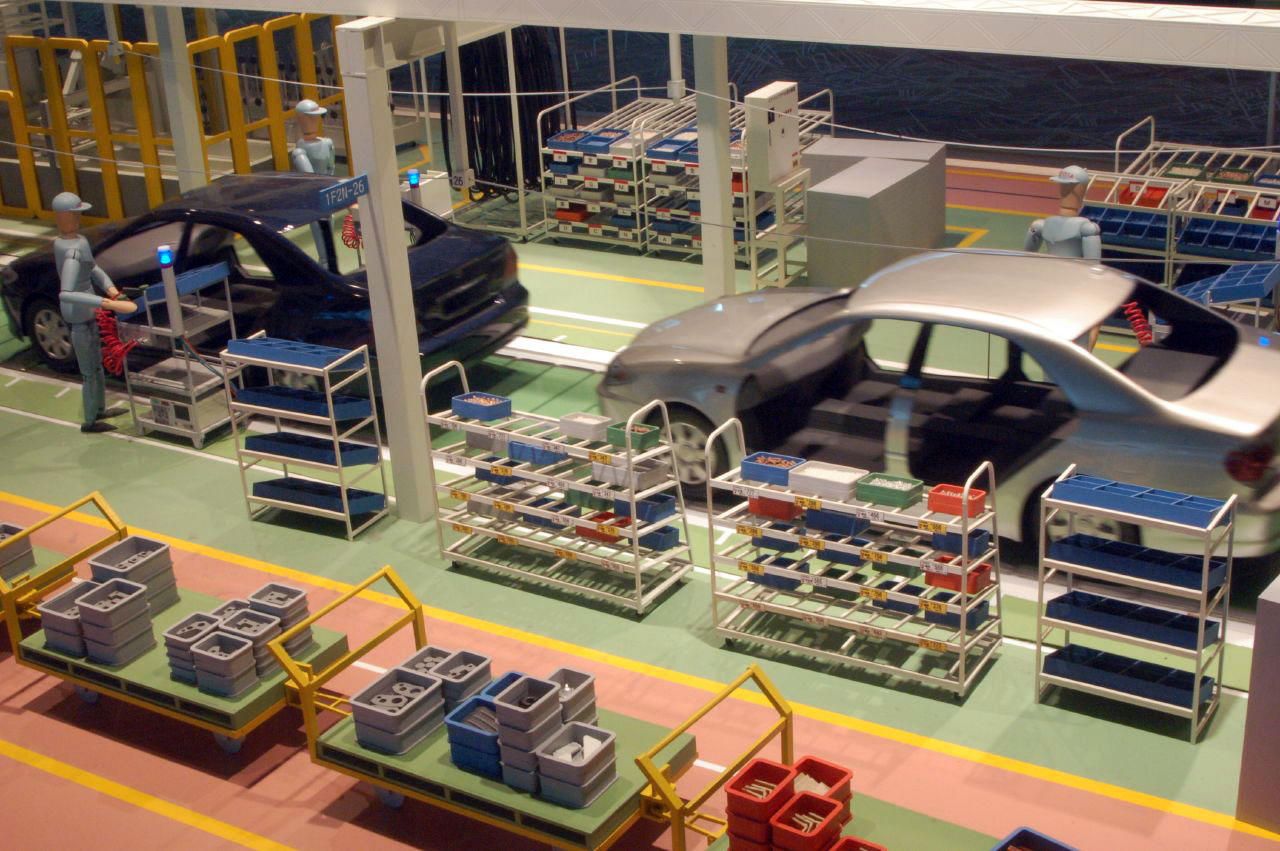

The principle of “build to order,” or pull came in with TPS. The principle was to have fast/responsive production, not manufacturing anything until an order was received, then manufacturing the product that matched the order. In addition to reducing inventory and WIP, it allowed tremendous flexibility in the manufacturing line and the ability to respond to customer requests. Before this, for example, manufacturing might build all blue cars, with the premium features, leather, all wheel drive and so forth. But what if someone wanted a red car with just the basic features. Pull systems created the ability to customize each product and build it in a very efficient manufacturing process. Red minimalist cars could be mixed with blue full featured cars, along with yellow, purple, green, white and black cars.

The dream behind pull manufacturing was highly efficient, yet highly flexible manufacturing. It was perfectly predictive because you knew which orders you had to fulfill, there would be no change, and you could manage the workflow very efficiently.

Marketing and sales people started applying this in the principles of inbound marketing/sales. A customer would make an inquiry, that inquiry would be handled then passed to the next person in the “assembly line” to be handled, all the way through closure. The problem with this concept in marketing and sales starts with the very first assumption behind the order that creates the pull. It was a fully configured order, it was from a customer who had committed to purchase that product. It specified “I want a blue car with these features on it.” Once that order was accepted in the pull line, there was no question the customer would accept it, there were no changes or variations in the process, so the line could be set up and optimized for production.

Of course these foundation assumptions are non existent in inbound sales and marketing. A query from a customer wasn’t an order or commitment. But more importantly, what the customer wanted could change at any point in the process or be stopped at any point in time.

So while manufacturing processes could be optimized for any mix of red, blue, yellow, green cars, with whatever features–because at the beginning of each day we had orders that would not change, you can see how this falls apart in sales and marketing. The customer is likely to shift their needs, priorities, anything at any point in the process, so what we had to do to respond to it changed completely throughout the process.

Underlying this and many of the other principles is the concept of variability. TPS and other lean processes work, as long as variability is minimized or eliminated. That means, the “order” doesn’t change once it’s started in manufacturing, that the steps we have to go through don’t change and so forth.

The problem with sales and marketing is that it is infinitely variable. Each customer in the buying process will change their needs, priorities and attitudes many times through their buying process. We have to deal with multiple buyers (the CEB’s 6.8) changing their needs multiple times through the buying process, often stopping and abandoning it at any point in time.

Finally, pull was fundamentally put in place to avoid overproduction. In sales and marketing, we are seldom worried with overproduction, instead being worried about having enough leads/opportunities to achieve our goals.

You can see how the principles of pull manufacturing are very challenging–perhaps impossible to implement with rigor in sales and marketing.

Principle 4: Level out the workload. This principle was tied closely to the previous principles to help improve the overall efficiency of the manufacturing process. Prior to this each step of the manufacturing process was treated somewhat independently. For example, if one step required a lot of time and processing, there could be a WIP pileup before the start of the step, and all the manufacturing line downstream of that step might be idle.

Leveling the workload sought to get the highest levels of efficiency out of the line. First manufacturers sought to eliminate WIP. They did this by breaking down manufacturing into steps that took roughly the same amount of time for each process. That way, each step finished their function in the same time, passed their work to the next step, which because it was on the same cycle would be ready to accept the work. This way the utilization of all the machines in the process was very high, there was no WIP and the process could be very efficient.

If you want to impress someone at dinner conversation, talk about this step and drop the words “TAKT time” every once in a while. They will think you really have understood this an the other principles.

There are some that would argue you can design a “sales assembly line” in much the same way. By specializing each of the functions, handing the customer off to each specialist you can create the efficient process. While in principle, it’s nice, in reality it’s unrealistic–and actually leads to huge inefficiencies. Each step in the process is highly variable–from step to step and from customer to customer. One customer might need more “demo time,” than another–they might need several demo times. One customer might need to be restarted in the process, others drop out along the way. There is infinite variability in the customer and what it takes to work with them through all stages of the buying process.

It’s because of this variability, many of the concepts around specialization that work in manufacturing actually end up making our processes very inefficient and unpredictable.

Another premise in leveling the workload is 100% quality. A way to look at this, is 100% of what is started is finished. If we start 100 cars down the line today, we will get 100 cars at the end of the line.

Clearly in marketing and sales this is unrealistic. In fact a very small part of what starts actually finishes, for any number of reasons. So this principle really breaks down in it’s application to sales and marketing.

Enough for now:

This is a long post. But it’s a very complex set of concepts. By understanding them, we can better learn which principles of lean manufacturing can really help in driving sales and marketing performance, and which actually have the unintended consequence of adversely impacting sales performance.

We’re almost through the toughest parts, it will start going faster in the following posts. Thanks for hanging in there!

Leave a Reply