Partners in EXCELLENCE - Making a Difference

"Toto, I’ve a feeling we’re not in Kansas anymore…"

Dorothy in the Wizard Of Oz

Most of us experience those feelings of uncertainty today. Everything is changing, at rates we’ve never experienced. Complexity, ambiguity, overwhelm, uncertainty, and ambiguity dominate everything we and our customers do.

It is in this complexity that sellers and leaders create real opportunity. Making sense of what we and our customers face, helping them understand and simplify, moving forward to take action.

Partners In EXCELLENCE works with leaders and sellers in mapping the journey from complexity to simplification. We help them OutSell and OutPerform all others.

Latest Posts

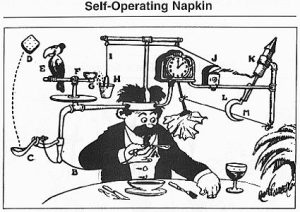

“Systems” Are People Interacting

When we look at our GTM strategies, ideally, we are leveraging systems thinking. We’re not just optimizing isolated functions or hitting departmental/individual KPIs, but designing […]

Read MoreMoving From “Doing More Things,” To “Doing Things That Matter More…”

We’ve been conditioned to think that productivity is driven by doing more things. We focus on scaling those things. Whether it’s more outreach, more prospecting, […]

Read MoreWords And Language Matter

Every week, I’m speaking with clients and colleagues around the world. Clients in Europe, the Nordics, Franc, Germany, Spain, Italy, the UK. Clients in India, […]

Read MoreLet Me Pose A Hypothetical Question…

What if we rethought our conversations–with our customers, with our own people? What if we thought, about why the best conversations don’t start with answers? […]

Read MoreRecent Podcasts

Sales Manager Survival Guide, The Rural Sales Show, St. John Craner Interviews Dave Brock

In this conversation, David Brock, author of the “Sales Manager Survival Guide“, discusses the evolving role of sales management, emphasizing the importance of maximizing team […]

Learn MoreBuilding Foundations in a Shifting Sales Landscape, Paul Fuller Interviews Dave Brock

In this episode of The Art and Science of Complex Sales, Paul Fuller sits down with Dave Brock, founder of Partners in EXCELLENCE. They unpack […]

Learn MoreIs Success Killing Your Business? A Conversation With Tim Ohai

You’re leading… but are you asking the wrong questions? In this episode of “How to NOT Execute Your Strategy”, author and master consultant, Dave Brock, […]

Learn MoreRecent Videos

Building Foundations In A Shifting Sales Landscape, Paul Fuller Interviews Dave Brock

In this episode of The Art and Science of Complex Sales, Paul Fuller sits down with Dave Brock, founder of Partners in EXCELLENCE. They unpack […]

Learn MoreDamon Lembi Discusses Selling With Dave Brock, The Learn-It-All Podcast

I enjoyed this discussion with Damon Lembi, CEO of Lernit Training. We covered a lot! The traditional way of selling in B2B businesses no longer […]

Learn MoreSecrets Of A CEO Whisperer, A Conversation With Tim Ohai

You’re leading… but are you asking the wrong questions? In this episode of “How to NOT Execute Your Strategy”, author and master consultant, Dave Brock, […]

Learn MoreWe live in a world of unprecedented change and uncertainty. At the same time, it offers each of us the opportunity to rethink everything we do, individually and organizationally. We have the opportunity to innovate and transform---ourselves, our organizations, our customers, and our markets. We have never seen a more exciting time in business and selling!

Partners In EXCELLENCE has had the privilege of working with individuals and organizations in mapping their innovation and transformation experiences, helping them OutSell and OutPerform all others.

As you embark on your own changes, reach out to us to help you think about the opportunity and how you move forward in making it happen!